GREEN RIVER RIFLE WORKS

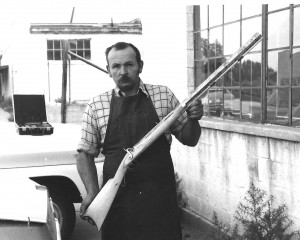

GRRW was Doc’s brainchild. It was incorporated in March of 1972. It started operations in DOC’s garage, later moved to a 8000 sq. foot warehouse in Roosevelt, Ut. DOC had been thinking about rifles for a production company for a long time, finally centering on a composite of Henry Leman’s later cross plains rifles. He made the first one, call it the prototype, in 1970. It is pictured below.

A Hawken prototype followed. See below. Note the walnut stock. It was also a composite, more Sam-like than J&S. The fore-end tip is pewter, as on the Leman. Both sported Douglas barrels. The furniture was what was available at the time. I (Doc) made a terrible mistake, experimenting to discover how fast I could make a rifle, start to finish, including all steps. The Leman took me ten hours, the Hawken twenty. I later discovered, no matter how much we tried, and even with precarved stocks and inletting machinery, where I started with a plank, that the average production time for employees was near twice that.

Hawken prototype

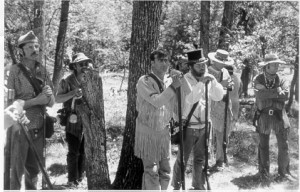

First employees

GRRW’s first employee and DOC’s great friend was Carl Walker, shown top above shooting the very first production Leman Trade Rifle, working on another and sanding a stock in his lap. Greg Roberts, pictured where he loved to be, hunting and rendezvousing, lower row, also became close.

You can see Carl Walker holding the very first production Leman (#101, in-the-white) in the left hand photo above. It’s also seen leaning against a post below. Leman #’s 102 thru 104 are in the top right photo. Doc is shooting #101 in the lower right hand photo and is seen loading it on a buffler hunt, right. He later took the rifle hunting sheep and caribou in Alaska. There’s further photo detail in ‘Doc’s Past Adventures”, 1972.

Second was Les Holt, left above, who was later killed when the Green River Black Powder plant blew up. Gardell Powell was third and is shown sanding a stock, middle above and Neil Fields draw-files a barrel, right.

Promoting GRRW

GRRW’s first effort at print advertising, 3 single pages stapled together and mailed free on request. DOC did the print and layout and also the not so artful artwork. It was cheap and effective in an enthusiastic market.

Other emplotees came later. Doc’s old friend Jim Summerall joined the crew as a lockmaker, Carney Pace came on once GRRW started making its own barrels, Simon is inletting a lock mortice, Parley Smart files a sight slot in a barrel. Pat Lakin machines a barrel.Rick Guthrie and Lynn Weimer share a joke,”Black” White grins over his machine work. He was called “Black” to distinguish him from “Doc”.

The first barrels GRRW used were Douglas, pretty good quality but couldn’t get enough of them fast enough to keep up with orders. It was obvious we were going to have to establish our own barrel shop after the first year of operation.

‘Blue Jacket’ Sanders (in the left hand photo) showed up just in time to improve product quality, Tanyu Howard (rght) was trained by Bill Large to make GRRW barrels and was the genius and moving force behind Green River Black Powder. The only known photo of the Green River Powder plant is the tower you can dimly see in the middle photo of BlueJacket loading a rifle. The tipi in the background behind Tanyu is where ‘Black’ White and wife lived for their first year, including a 20 below winter.

We called the belt driven planer shown left above ‘Grandpa’. It came with the deep hole drills and P&W rifling machine that DOC bought from Bill Large. It was soon replaced by a huge 12 position semi-automated machine for faster and higher quality production. Middle: “Horny Skunk” Brandenburg congratulates Rick Guthrie, an ardent traditionalist, on a buffler kill. Guthrie contributed a lot to the accuracy of GRRW’s reproductions. Right: Here is DOC pointing out the prototype Leman Indian Rifle (top), Leman Trade Rifle (middle), Little Leman (bottom), about 1974.

Charley Winn ran the carving machine part time and seemed to love it. Here are 9 of the first Leman Trade Rifles ready for final finish. The dog is Ralph. Bill Brandenberg was office manager, shown here with a sage grouse. Some say that Ralph was smarter than Bill. Ralph would bark for ‘like’ . If you asked, ‘Do you like girls’, Ralph would say ‘woof”. So would Bill.

Greg ‘Grizz” Roberts came from Colorado to manage the operation. He put his heart and soul into the company, improving quality and managing the tender feelings of the artistic GRRW crew. I still remember the lecture he gave me for dirtying up ‘his’ bead blaster. Left above, Gregg and Ed Trump \on the Green River 1972, Right above- he shoots the very first flintlock GRRW fullstock Hawken. Lower left – a duck bites the dust, Lower right, A float down Green River.

Doc and “Grizz” met at the Chadron Rendezvous 1972, later hunted buffer traditional style. He had a lot to do with the fame that GRRW products eventually aquired.

Left:This is most of the crew in 1974: top from left – Carl Walker, Greg Roberts, Gardell Powell, Tanyu Howard, “Black” White (who lived in a tipi through a Uintah Basin winter his first year here). Bottom from left- Ed Trump, Simon, who I don’t think had a last name, Russ Snaith, an unknown (sorry), Ron Paul and “Blue Jacket” Sanders.

LEMAN RIFLES

The very first GRRW Indian Trade Rifle, made by “BLueJacket” Sanders in 1974, recently found right here in Roosevelt, hidden for the past near 40 years. It was modeled from an original once in Doc White’s collection, later stolen from the GRRW factory.

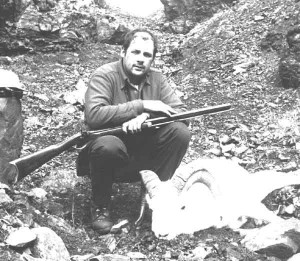

As always, a new rifle was an excuse for a hunt. Here is DOC with that first production Leman #101, an Alaskan Dall sheep and Barren Ground caribou, Fall, 1972.

GRRW gets famous

Above are the cover and insides of GRRW’s 1975 brochure. DOC did the design and layout and wrote the print work as well. He even designed the oval GRRW logo, which eventually became a belt buckle. There are only 50 of those in the whole world. By late ’75, GRRW was making ‘Plum Center” barrels for sale into the general market as well as for in house use. They gained an enviable reputation for accuracy.

Above is one of the early Leman Trade Rifles with Kern coil spring lock and the heavier brass furniture then available with the bulkier stock required to match the furniture.

Later, the Leman was revised after GRRW aquired more traditional and proper furniture. We can thank ‘Blue Jacket’ Sanders for the accuracy of the furniture and conformation. He was a master toolmaker. The GRRW Leman pictured above is typical of production in GRRW’s last few years. This one was put together by Bill McKay, serial # in the 600’s. His family owns it now. He died of a pulmonary embolus after a knee operation in 2000. He was working for White Muzzleloading at the time.

The Leman rifle above was built by Carl Walker from a kit sold to a local client in the 1970’s then stored unbuilt for near 50 years. It is the most striking maple ever seen on a GRRW Leman.

GRRW rifles are hard to find these days. Most stay in strong hands, few owners sell them. They have become quite a collector’s item and command high prices.

HAWKEN RIFLES

The Hawken rifle had become known as the epitome of cross-plains and mountain rifles. GRRW made many of them, the most famous of which was the commemorative of the Jim Bridger Hawken commissioned by the Montana State Historical Society GRRW had the original rifle on hand for 3-4 years. The original rifle is pictured below left. Naturally, we took it apart and photographed it. Those photos will eventually show up on a page dedicated to the Jim Bridger Hawken. Pat Lakin is shown below holding the original and Carl Walker is shown in three veiws with an early GRRW Bridger reproduction ‘ in-the-white’.

The photo collage below is the #1 GRRW commemorative of the Jim Bridger Hawken. It is marked by Gardell Powell. It was discovered at a Denver gunshow just this year. (2015)

Other Hawkens

Below is an example of a well used GRRW Hawken 54 caliber rifle. This one is the earlier , lighter model that many like to call a “Carson” Hawken because of the lighter 1 inch diameter barrel. The well known Carson rifle in Santa Fe is about this size and conformation. This GRRW rifle is also marked by Gardell Powell.

The owner has added decorative tacks to the rifle plus inletted a couple of bear claws to the stock, perhaps a trophy from a kill.

Below is another example of the lighter “Carson” style Hawken rifle.

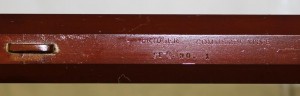

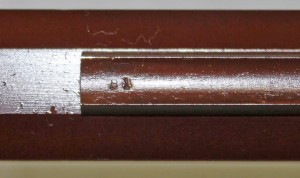

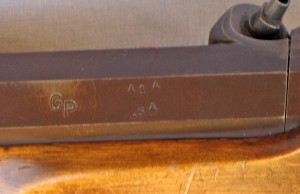

This one is clearly an early production rifle. It is serial marked H- 030, number 30 of all those made. It has a Douglas barrel, which was the brand used early on, all other details are clearly GRRW. It does NOT exhibit a maker’s mark. Maker’s marks were added routinely only after the first 80 or so Hawkens were marketed.

The surround on the cheekpeice is unusual, such a surround was not a standard option. The cast pewter nosecap was indeed the usual production practice at the time. iron nosecaps came later. These features suggest that this rifle was sold assembled but unfinished ‘in the white’ and the custom features were added by the client. If so, he did a nice job and it has held up well.

Below is another example of the Bridger style half stock Hawken rifle, this one in 69 caliber, 1 1/8 X 1″ , 36″ long taper barrel Side opener iron patch box, German silver trim. Long bar Hawken rear adjustable sight. A fancy reproduction of the Bridger Hawken rifle that GRRW had here in town for a few years back in the 1970’s.

This one was built by DOC and is signed by him. Any Bridger rifle that shows up with DOC’s ‘GBW’ cipher on the barrel is NOT an original GRRW. He never built one back then, only later. You will note that the furniture on this rifle is antique hot rust blued, something that GRRW never did, their furniture was always browned.

GRRW pistols are even more rare and desirable. A few of them are pictured above. There was no ryme to them, except ‘Western Fur Trade’. All were custom, design dictated by the client’s order.

The “Poor Boy”

The ‘Poor Boy’ was conceived, embodied and birthed by Greg Roberts. It was meant to be an affordable but high quality rifle. There was a stock, barrel, lock, trigger and trigger guard and little else. All furniture was cheap iron. The fancier ones had a grease hole in the buttstock and a nail for a butt-plate and occasionally a double-set-trigger. Most were long and light.

Above is one of the last, made in 1980, serial # 262, this one signed by Neil Fields, 7/8″ octagon barrel in .45 caliber. Awfully plain but beautifully designed and executed.

GRRW Barrels

GRRW barrels started their life as a bar of 12L14 steel, The round bars were 20 feet long. The bars were cut to rough length, then the ends were trimmed in a turret lathe. They were then deep hole drilled to caliber on one of two P&W deep-hole drills, then were moved to one of two P&W 1/2B X 50 cut rifling machines and rifled with 7 grooves, usually 12+ thou deep. The barrel was then turned 14+ degrees and the lands were cut, just barely trimming off the burrs from deep hole drilling. The barrel blank then went to the planer, where 8 at a time were cut to octagon, one flat at a time. Then the breeching was cut and milled in and the muzzle cut and trimmed to length. It was a long and meticulous process. Any screw-up anywhere along the line and the barrel was junk.

GRRW Stocks

The stocks started life as a plank, kiln dried and 2.5 to 3 inches thick. The planks were bandsawed into blanks, then cut to rough size on a modified furniture carving machine. Later GRRW aquired a rotary 4 place cup cutter carver that did a more consistent job. Once 5 axis pantographs were developed, GRRW switched to purchasing the carved stocks outright for the standard guns. Nowadays, CNC pantographs are used for the same purpose, Once the stock was rough carved, the barrel channel was cut, cuts for tang, buttplate and lock were milled in with small individual pantographs.

Then the gunstocker refined the inlettting and shaped the stock, a process that required lots of skill and practice. Of course, the truly custom guns were built from the plank.

Final Finish

Initially, the gunsmith who did the inletting and shaping also did the sanding and finishing. Later, as orders and employees accumulated, the work was assigned out to those who did it best and fastest, creating three departments. The metal parts were fabricated in the barrel shop, the gunstocking was done by the skilled and experienced smiths and the sanding and finishing was done in the finish shop, where females reigned supreme. GRRW had a female smith or two but never a male finisher. The ladies were fantastic. Where a man had to stop his hands to talk, these girls could talk and work a mile a minute without harming either activity.

Left:A lineup of Leman rifles waiting sale or shipment. Middle:Another lineup of mostly Hawken rifles awaiting their fate. Right: A scene from the finish room: sanded and stained stocks awaiting final finish with oil and elbow grease.

Recreation

The GRRW folks often recreated together. Picnics summertime, bird and buffler hunts in the fall—

Young cow eats a lot better than old bull!

Young cow eats a lot better than old bull!

Here’s ”Grizz ‘ taking one down. A shot to the head only stuns the bull. The skinner comes up with a knife when the bull starts to get up, ‘Grizz’ whirls and shoots. Center shot makes meat. A whole lot more real than in the movies.

Here’s ”Grizz ‘ taking one down. A shot to the head only stuns the bull. The skinner comes up with a knife when the bull starts to get up, ‘Grizz’ whirls and shoots. Center shot makes meat. A whole lot more real than in the movies.

The GRRW gang 1975