The following is a listing of DOC’s designs and inventions. Some of them became fairly famous, some went nowhere. DOC always was the inventive sort, born with an Idealist personality with only a little bit of Rational thrown in as a weak second. As such, inventing was second nature. Teaching the doctrine of the inventions came just as naturally. All this was a profound influence in his life, culminating in the organization of Green River RifleWorks back in the 1970’s and then White Systems/WhiteRifles in 1991.

The Hawken rifle

|

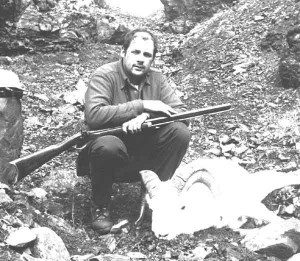

| Doc in 1975 with a Hawken Rifle from GRRW and a buffalo from Nebraska |

It should be obvious that I didn’t invent the Hawken Rifle. Sam and Jake Hawken did, using the best of American barrels with their deep grooves and slow twist for round ball and mounting it in a stock that , except for the curved American buttplate, looked very much like an English Sporting rifle. I had the privilege of handling quite a number of Hawkens, 32 of them if I remember right, shooting two of that number back in the 1960’s and 70’s, when they were cheap and first coming to fame and prominence. Most are now in permanent collections and are worth a fortune.

The Hawken is a complex rifle and did not lend itself to easy manufacture, which is why most modern ‘Hawkens’ are barely similar to the real thing. As ardent traditional muzzleloading enthusiasts, we at GRRW wanted to make our rifles as close to the real thing as possible. The effort resulted in me designing the tools to manufacture the gun as quickly and efficiently as possible. A 6 place furniture carver helped, it at least roughly formed the gunstock. A series of small single use mills were developed and used to cut the lock mortise, buttplate curve, tang and trigger plate mortise. These tools facilitated the handwork that completed the inletting of the gunstock to fit the parts. All the Hawkens produced in those early days were custom, but many of the parts were standard which eased the use of the small machines. Even with the machines, it took about 40 hours of labor to fully finish a Hawken rifle, including manufacturing the barrel, fitting the breech and tang, carving the stock, cutting in the mortises, then hand fitting each part, then file finish shaping, sanding, staining and varnishing the stock. In the meantime the metal parts, once fitted, were likewise finish shaped, sanded, polished and then browned. At least 5 skilled workers were involved in the production of a Hawken, or indeed, any GRRW rifle.

The Leman Trade Rifle and Leman Indian Rifle

|

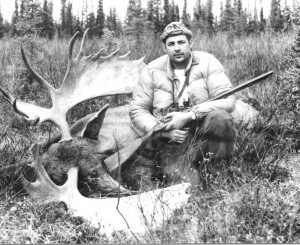

| Doc with the very first Leman Trade Rifle, Alaska, 1974 or so. |

Leman made rifles of all types and varieties, some cheap for frontier use and some expensive for the gentry. One would almost think that there was a pile of parts in the middle of the floor in Leman’s factory and the smiths grabbed the first available thing for whatever they had in hand. If there was any central theme, it seemed to be tremendous variation.

The Leman Trade Rifle design was a compromise. I designed a plain, easy to manufacture but sturdy and effective hunting rifle that at least in general represented the half stock Leman rifles found on the Western Frontier. Thus the brass furniture, standard inch wide octagon 33 inch barrel, single key, single trigger, plain short tang and drum/nipple combination designed into the final product. It was much easier to manufacture than the Hawken, using its own set of small carving machines. Many were custom ordered, with patch boxes and double set triggers. Most took about half the time to make as did a Hawken, using the same processes and similar tooling.

The Leman Indian Trade Rifle was an amalgamation of the few surviving full stock Leman rifles in Western collections. As we designed it, I say we because I wasn’t the only one interested in the project- “BlueJacket”, Phil Saunders, was especially helpful, it used a thicker 1 1/16th inch octagon barrel again 33″ long (but often shorter on custom order), plus a slightly slimmer full stock in mostly maple or sometimes walnut. The rest of the furniture was standard Leman brass as made for the halfstock with the addition of brass ferrules for the ramrod. It took only a little longer to build than a half-stock Leman. There were relatively few made compared to the half stock. GRRW had their Leman brass butt plate and trigger guard custom cast, using a special black sand (lost wax investment casting was not available then) but the custom made casting plates have long since disappeared, which is sad as the design was especially authentic.

The Poor Boy

There was a demand for a less expensive rifle than the Leman or Hawken in the 1970’s. Our response was the so-called “Poor Boy’. It was full stocked, no buttplate, single trigger, 3 pins instead of keys, two forward ferrules only, no fore-end cap, plain as a yard of pumpwater kind of rifle. Greg Roberts, who was manager at the time, contributed heavily to the design and final product. His insistence on quality was famous. There was a nail in the tip of the butt and a piece of horn for a toeplate- there were other features, like DST’s, on custom order and at extra cost. GRRW made quite a number of them, but few in comparison to Leman and Hawken rifles. I’ve never seen one back in the market. The small machinery invented for the other guns adapted fairly well in this instance.

[one_half] [/one_half]

[/one_half]

[one_half_last] [/one_half_last]

[/one_half_last]

Facsimile of cover and inside page from GRRWs 1974 brochure detailing the looks of their semi-production rifles.

GRRW Barrels

While I didn’t exactly invent barrels, I did design the interior of the barrels that GRRW manufactured. This particular story started in 1972 when it became apparent that GRRW could not acquire all the Douglas barrels it needed, on time, for production of its famous rifles. Delivery in those days was terrible and they were expensive, payment being required up front. My old friend Bill Large was slowing down at the time, age catching up to him, and he sold me a Pratt & Whitney 1/2B x 50 rifling machine and a deep hole drill and planer to match. I acquired another set in Salt lake City when Rocky Mountain Arms went out of business. We modified a huge hydraulic planer to plane near a dozen barrels at a time and installed the turret lathes and other small machines needed for muzzleloading barrel production. It was then that we discovered why delivery was so sporadic. The problem lay in delivery of barrel steel. It took about a year to get GBQ (Gun Barrel Quality) steel from the foundry. What a mess.

Since the Hawkens had used 7 lands and deep grooves in their rifles, we had to, too, so the machinery had to be re-tooled. We spent so much money getting all this done and buying a huge quantity of barrel steel that I could not afford a production bore reamer. We ended up cutting the top of the lands with the same cutter that was used to cut the grooves. This was labor intensive but resulted in fantastic accuracy. It proved to be a better technique with improved results over the reamer anyway. We sold thousands of barrels into an enthusiastic market until Carter’s inflationary recession killed the Co. In 1980.

Semi -production manufacturing-

Was a concept that I came up with, not so new in reality as many manufacturers in the past have used similar processes. I was merely the first to formally name it and define the process. Most custom makers now use it. They may not know it, but the availability of 5 axis carving machines, lost wax investment castings, and a plethora of nicely manufactured CNC parts that need little final finishing all contribute to the concept. The secret, of course, is the availability of parts that are an almost -fit for the stocks available. This could not have happened without modern machine tooling and techniques.

White Muzzleloading System

I had long admired Whitworth’s contribution to the shooting sports. He was not only acknowledged as a genius in his own time but was also a supremely successful businessman. His systemization of machine tooling still affects modern tool making and use. He used a thoroughly modern scientific method of discovery and development. This systemization of development resulted in his being chosen by the British military to further develop the Enfield percussion Minie ball rifle of 1853. The final result was the fabulously accurate and famous ‘small bore’ .451 caliber hexagonal bored sporting-target rifle using a 520 grain slip-fit bullet. The rifle proved to be deficient for military use as the bore dirtied too fast, but it promoted a rage of long range shooting. Later the system was improved by Rigby and Medford, using rifling that looked very modern, same twist but shallow grooves and bullets of round cross section in both lubricated and paper patched form. I longed to own one.

I also came to love double barreled rifles. In 1964, while interning at LDS Hospital in Salt Lake City, Ii acquired a John Hayton built British percussion double. It had a nice stock, functional locks and triggers but the original 52 caliber 2-grooved barrels made to shoot a winged bullet were a mess. The rib was loose and the bores pitted.. I decided to rebarrel it, something i had never tried before and decided to use a pair of Douglas .458 barrels with 1-20 twist. I had a friend turn them to original shape on his lathe and install the original breeching. I cleaned up the original rib and barrel furniture and eventually reinstalled them. I bought a lyman mold for the .458 caliber 475 grain bullet designed for the 45-110, but found that forcing the full sized bullet down the barrel was impossible, even with the softest lead. It was then that it occurred to me that the hexagonal whitworth bullet was slip fit and that later whitworth bullets were round in cross section, designed to expand into the hexagonal bore. This prompted me to size the 475 grain bullet down, eventually, to 451, which i found loaded easily and shot superbly well.

|

| Doc with re-barreled John Hayton rifle and moose, on the Chistochena, Alaska, |

Over the next 2 years, including a stint with the US Army in Alaska, I regulated the barrels so that they shot into a cup sized group at 100 yards. With 75 grains of Dupont fffg black powder, the double shot just like a 45-70, a real game killer. I used the rifle for years after that before sorrowfully trading it off, knowing I could always build another.

That rifle was the basis of the White Muzzleloading System. When later I designed the bolt action that eventually morphed into the Super-90, then Super -91 and Super-91-ll, the M98 Elite hunter and finally the Thunderbolt, it was natural to use barrels adapted for the long, heavy, high BC bullet technology that Whitworth pioneered. I had the advantage of modern steels, finely crafted button rifled barrels with precise tolerances, available from multiple sources in standard calibers. It should be obvious that the DOC-designed .451 bore is merely a modern .458 barrel with 1-20 twist and .035″ grooves. Likewise the White .410, which is a modern .416 barrel with 1-16 twist and .035 grooves. The .504 is a modern .512 barrel with 1-24 twist and .004 grooves.

[one_half] [/one_half]

[/one_half]

[one_half_last] [/one_half_last]

[/one_half_last]

White logos, earliest on the left, latest on the right.

White SuperSlugs(PowerPunch) bullets on the left. PowerStar(SuperStar) bullet on the right with see through sabot.

The bullets were easy, too. I adapted the design of that first 45-110 475 grain multi-channelured, lubricated bullet to each caliber, with final lubricated diameter .001 smaller than the nominal caliber so it would slip-fit through powder residues from the previous shot yet still be accurate. MOA groups were not uncommon with the best energy and down range performance in the business. Later, when sabots became popular, I designed the White channelured , lubricated sabot with comparatively heavy, high BC lead hollow point bullet that White Rifles later named the PowerStar. This combination’s sabot was .001 oversize, which made it slightly harder to load than the slip-fit all lead bullets, but which held the bullet in the sabot while in the bore. It also proved to be a devastating killer on game up to elk with MOA groups becoming the norm.

The cover of the first edition of my book, “The White Muzzleloading System”, which was an attempt to sell the long, heavy bullet, slip-fit system that I developed, based on Whitworth’s earlier work. It did not sell well. One reader said that he needed a PhD to read it. Too many sophisticated arguments, maybe. You can read it for free on this website now. GoTo ‘DOC’s Books and Articles, then click on “the White Muzzleloading System” to read.

The cover of the first edition of my book, “The White Muzzleloading System”, which was an attempt to sell the long, heavy bullet, slip-fit system that I developed, based on Whitworth’s earlier work. It did not sell well. One reader said that he needed a PhD to read it. Too many sophisticated arguments, maybe. You can read it for free on this website now. GoTo ‘DOC’s Books and Articles, then click on “the White Muzzleloading System” to read.

Industrial size manufacturing philosophy

One of the things about modern gun companies that always bugged me was their penchant to design and sell custom tools for their products. I guess they make more profit that way. Early on, I decided that the consumer friendly way was to use standard industrial sizes and commonly available industrial tools as a basis for my designs. That is why DOC-designed guns use Phillips or hex head screws rather than traditional thin slotted gun screws requiring a custom thin bladed screwdriver. This means the hunter can carry a tiny lightweight L-shaped tool for takedown rather than a much larger and bulky screwdriver. I also tried to use just a single size for any design, so the hunter would have to carry only one size to strip the gun. This philosophy also applied to the nipples and nipple-breechplug that I designed. Instead of the old two sided nipple, requiring a special tool, I designed them with hex heads so that common hex-head tools available at any auto or hardware store would install or remove them.

Functional Elegance

is a term I invented for the design philosophy that I follow. It basically means that the designed item, be it a gun or whatever, should be so ergonomically simple and functional, so user friendly, that any person could readily and easily see and feel how to use it without having to read an instruction manual. Just handling the item briefly would teach the doctrine of use. It also meant that despite being so simple and functional, it was also elegant enough to draw the eye to it, to pick it off a page, or out of a collection of similar items automatically, pulling the prospective user to it without words or tag lines. This makes the item easy to use and consequently easy to sell.

White breech -plug-nipple combination-

came abut because of the penchant for nipples to swell with the pounding of the hammer until the cap would no longer fit. Usually this happened right in the middle of an important hunt. In the early years, it was common to carry an extra nipple and nipple wrench so that a quick change was easy. A better answer was to make the nipple out of tool grade oil hardening stainless steel, stainless because it resisted burn-out better than ordinary steel, was initially easier to machine and would harden to standard using common industrial techniques. The goal was no significant deformation with a lifetime of strikes.

|

|

DOC designed nipple-breechplug |

Breech plugs were also a problem in early in-line rifles. Most competing designs were overlong, for strength I suppose but made of common steel. Instead, I designed a much shorter breechplug made of oil hardening stainless steel, bringing the Rockwell hardness number up to that of a Springfield ‘06 action, hard enough that a common file would not cut it. Adding the nipple to the breechplug seemed the right thing to do. White Systems had such confidence in the design that they were guaranteed for the lifetime of the original buyer. Time proved that they were a bit over-confident. If not hardened just right, the nipples would eventually peen and bulge to the point that a cap was difficult to fit, but it took about 5000 strikes to do it, more shots than most hunters ever take.

W-series rifles: Super-91 and Super-91-ll

I had conceptualized the bolt action that eventually became the W-series rifles as early as 1968. During the GRRW days, in the 70’s, I made the first such action, a fair copy of a Springfield bolt action, as a joke. Being a bunch of traditionalists at GRRW, we laughed and went about our business. The action sat on a shelf for near 15 years until Tony Knight brought out the MK-85 in the late 80’s. I immediately saw that my action was an improvement over his and determined to bring it to market. The action needed a bit of tuning, the then problem being the bolt handle, but I had it ready for market in mid 1990 without the bolt handle and featuring a pullcock similar to that on the Springfield 03. I personally hand made 60 of the rifles, designated the Super-90, wrote a 4 page brochure, mailed out 500 copies to selected Utah clients and sold every on of that first 60 by Christmas.

Left; A facsimile of the cover page of that first 4 page brochure sent to 400 Utahns as a test market in 1990. All 60 of my hand made rifles sold within three months, which is a sales percentage of 15%, very encouraging for a new company.

Encouraged by the fast sales, I organized White Systems in 1991 and started production of the newly designated Super-91. After several years of brisk sales, we came to realize that the Super-91 under-rib was a problem. It was expensive to manufacture and caused accuracy problems. The rifle did better without the rib. We had also discovered that the spring loaded detent holding the hammer body in the action was easily abused and required a re-design. Thus came about the Super-91-ll, without a rib, thimbles being attached directly to the barrel and with a thumbscrew detent replacing the original spring-loaded detent. Otherwise, the rifle was the same and sold every bit as well.

On the left above is a Super-91 rifle in stainless steel with a B&C fibercomposite checkered stock.

Left below is a blued Super-91-ll with gray laminate stock. Both were standard production items.

After the failure of White Systems in 1995, the company went through a transformatative re-organization and became Muzzleloading Technologies, Inc. There was a need to separate MTI products from those that White Systems had produced. I was asked to redesign the Super-91. In the meantime, I had been experimenting with rifling and discovered that truncated rifling was superior to the straight sided rifling in universal use at the time. We also found a superb barrel maker and Criterion barrels became our standard. The promise of superior accuracy was so good that I added a slightly heavier straight tapered 26 inch barrel. Otherwise, the M98 retained all the features of the previous Super-91-ll.

Here is DOC’s personal M98 Elite Hunter in stainless steel with buttstock mounted elastic SuperCharger carrier, aluminum ramrod, adjustable sling and Leuopold scope on Warne QD mounts. It shoots a .504 caliber, 600 grain PowerPunch bullet with 120 grains 777 powder with real authority.

Here is DOC’s personal M98 Elite Hunter in stainless steel with buttstock mounted elastic SuperCharger carrier, aluminum ramrod, adjustable sling and Leuopold scope on Warne QD mounts. It shoots a .504 caliber, 600 grain PowerPunch bullet with 120 grains 777 powder with real authority.

ThunderBolt

The White ThunderBolt came about because of the popularity of the then- new 209 primer. All of my previous designs had used either the small #11 cap or the larger musket cap. They had been quite successful because of my superior nipple-breechplug. All I did was adapt the old bolt action that I had originally designed and which became the W-Series to the M-98 Elite Hunter. I designed it so that the 209 primer was firmly held by the bolt against the breech face, largely preventing the escape of powder gases to the rear. An inadvertent advantage was that the 209 need not be separately removed after a shot. Just reload the rifle, pushing the new bullet down the bore swiftly with the ramrod. The air pressure developed would pop the old 209 out of the primer pocket most of the time, especially if the rifle had not been fired more than 4-5 times. Once the pocket was filthy, this did not work. As it turned out, the T-Bolt is just an M98 with a bolt and a 209 breechplug. Looking back at the procession of designs, I wonder why I didn’t just design the T-Bolt in the first place. It has become the quintessential White Rifle.

White ThunderBolt in stainless steel with Gray laminate stock and aluminum ramrod. Below is a photo melange showing the bolt action and breeching system for 209 primer.

[one_half] [/one_half]

[/one_half]

[one_half_last] [/one_half_last]

[/one_half_last]

[one_half] [/one_half]

[/one_half]

[one_half_last] [/one_half_last] G-series rifles: Whitetail, Bison, M97 Whitetail Hunter and M97 Lite

[/one_half_last] G-series rifles: Whitetail, Bison, M97 Whitetail Hunter and M97 Lite

White Systems was busy producing the Super-91 when David Gumucio brought me the basic idea for a simple slam-fire muzzleloading rifle. We met over lunch one day, where he timorously drew the concept on a napkin. He had just survived a bad experience with Knight Rifles and was reluctant to divulge his thinking, fearing that I might take advantage of him. I had a prototype made by the following week-end, and designated it and the guns to follow the G-Series. He was vastly flattered. White Systems ended up selling more G-series guns than it did W-Series. The G-series proved to be an ergonomic, functionally elegant and powerful hunting rifle. Gumucio came to work for White and ended up as general manager eventually.

Whitetail- The first of the G-series was the Whitetail. It was a simple rifle with only 2 moving parts and a total of 10 parts including barreled action and stock. It originally featured a slam-fire bolt with cocking handle on the left (like modern sub machine guns), White nipple-breechplug, White barrel, Bold trigger with trigger safety on the right and B&C fiber-composite stock. It’s only eventual problem was a single action bolt which attached to a small silver soldered lug. With the huge, hard kicking loads that a few hunters insisted on using, a few lugs tore off, usually due to a poorer than usual silver soldering job. This situation was repaired by welding on larger recoil lugs in later production.

[one_half] [/one_half]

[/one_half]

[one_half_last] [/one_half_last]

[/one_half_last]

Left: a Stainless Whitetail with camo stock, Williams sights and Delrin ramrod. To the right is a look at the left sided cocking knob, designed to be cocked with the weak left hand while the stronger right hand stays on the pistol grip with finger near trigger, much the same concept as on modern sub-machine guns.

Bison- was merely a G-series rifle with a 22 inch straight non-taper blued bull barrel and a less expensive wood stock. They were universally accurate and rarely show up in the used gun market. I have had exactly one returned for repair in the last 15 years

DOC White with a .540 caliber Bison with custom laminated stock and a fine early season Missouri whitetail 1994

DOC White with a .540 caliber Bison with custom laminated stock and a fine early season Missouri whitetail 1994

M97 Whitetail Hunter- With the re-organization of White Systems into MTI in 1995, I re-designed the Whitetail into the M97 Whitetail Hunter. The M97 looked much like the original Whitetail, but with a slightly heavier straight tapered barrel in lengths up to 26 inches rather than just the 22 inch length of the Whitetail. I also added a second stock bolt at the rear of the action and re-designed the front bolt to thread directly into a larger recoil lug. Otherwise, the M97 looked like a slightly heavier Whitetail with all parts except the outside barrel taper, stock bolts and recoil lug being the same. The M97 also used the superb Criterion barrels and were super accurate with White slip-fit bullets and sabots.

M97 Whitetail Hunter with B&C fibercomposite stock with Spiderweb finish

M97 Whitetail Hunter with B&C fibercomposite stock with Spiderweb finish

M97Lite- Despite the success of the M97, some hunters protested that the barrel was too heavy, preferring the lighter weight of the original Whitetail. Eventually, White Rifles heard the message and brought out the M97Lite, which simply put was an M97 with an original weight Whitetail barrel on it. Not many were made, as this was close to cessation of rifle production. No rifles of any model have been built since 2000.

M97Lite with 22″ Whitetail weight barrel and laminate stock.

M97Lite with 22″ Whitetail weight barrel and laminate stock.

SG series –

White Systems had long thought about an even simpler G-series rifle with a one-piece barrel and action. This would avoid the tooling for action-barrel connection. There was also a demand for an even lighter rifle than the Whitetail. In response, I designed a light-weight barreled action with G-series features but with the trigger safety on the left and the cocking handle on the right and with a one inch diameter one-piece, barrel and action. The stock was light weight beech, painted black, the trigger guard Delrin instead of steel. White did a single production run of the rifle in 1995. We called it the White Lightning. They were immediately and immensely popular. I have only seen a few come back for repair or sale.

Stainless White Lightning rifle with black painted beech stock and scope, Delrin ramrod.

Stainless White Lightning rifle with black painted beech stock and scope, Delrin ramrod.

BG-series shotguns: Tominator and White Thunder shotgun

The advent of the G-Series rifles gave me a chance to complete a project I had long anticipated: a superior muzzleloading shotgun. I had personally made a few shotguns based on the W-series action but the gun turned out to be too expensive, at the time, for brisk sales. The G-series was more adaptable to a high quality but less expensive shotgun but the action was too small for a 12 gauge barrel. I re-designed the smaller G action into the BG-series (Big Gumucio), using the same parts for interchangeability, except for a nipple-breechplug that would fit a 12 gauge barrel. I had long noted the superior performance of a straight rifled shotgun barrels, mostly seen in high quality trap guns and contracted with Hastings for straight rifled barrels and chokes. Lo and behold, Hastings barrels are made in France with an Italian rib and , guess what, delivery was sporadic and slow. The Tominator, a name coming from Gumucio’s fertile imagination, was a grand shotgun with superior performance, but delivery was awful because of French and Italian business practices. The White Thunder was a less expensive shotgun, only because it had a cheaper black painted beech stock instead of a more expensive laminated stock.

Tominator shotgun, best in the world. Was then, still is!

Tominator shotgun, best in the world. Was then, still is!

The big problem with tight choked muzzleloading shotguns like the Tominator was the tight choke. The Hastings chokes used for turkeys measured .660, making it impossible to force in a .730 bore-sized plastic shot cup. The solution was a tapered shot cup, the kind used in the Winchester AA magnum hull, available from Ballistic Products. It was perfect . The bottom end of the plastic cup was small enough to fit the ,.660 choke and the plastic was soft enough to be banged through the choke using the small end of the ramrod. The loading sequence that I developed became: powder first, then 2 each 1/8th inch Wonder wads or a 1/4 inch equivalent, then the tapered plastic shot cup, then the shot, then a card top wad. The thin card would bend to go through the choke then pop open to hold the shot in place. 90% first shot patterns were common.

Sporting Rifle

Whitworth’s original rifles were of course formulated to meet the demands of the British market of the 1850’s and 60’s. As such, they were half-stocked, with a shotgun butt, iron mounted, usually mounting octagon barrels and a single set trigger and long range folding sights. They also sported the latest heavy metaled Manton designed breech and a leaf spring percussion side-lock. They were elegant, expensive rifles. The only thing really unusual about them was the barrel bore, which was hexagonal with a fast 1-20 twist in .451 caliber. They became the basic rifle of the then new long range target game that culminated in the Creedmore matches between American and British teams on Long Island at the Creedmore Range in the late 1860’s. They were also widely used for hunting big game and later came to be designated ‘sporting-target’ rifles because of this potential for dual use. The White sporting rifle was merely a re-design of the original concept, using the same Manton designed hooked breech and leaf-spring percussion side-lock, but adding a recoil pad to the shotgun butt and tapered round White manufactured barrels in White calibers in a pistol-gripped laminate stock. Despite the simplification of the design, they were relatively difficult to manufacture and remained relatively expensive. They did not sell well, despite the classic design, in a market dominated by in-line rifles.

All Sporting Rifles have been and currently are custom made by DOC. Above is a .451 with tapered octagon barrel, pistol grip, checkered butt, and flip-up long range sights meant for both sporting and target use. All Sporting Rifles share the massive Manton designed breech shown right above. It’s far stouter than any other breech system known. All also are mounted with Henry style flat spring percussion locks with drip bar.

All Sporting Rifles have been and currently are custom made by DOC. Above is a .451 with tapered octagon barrel, pistol grip, checkered butt, and flip-up long range sights meant for both sporting and target use. All Sporting Rifles share the massive Manton designed breech shown right above. It’s far stouter than any other breech system known. All also are mounted with Henry style flat spring percussion locks with drip bar.

BG-Series with Inter-changable barrels

This was not the most elegant, but it was the most functional rifle-shotgun that I ever designed. It could be used either left or right handed, and accomodated both shotgun and rifle barrels. It was a simple, straightforward design with only 5 moving parts: the hammer (fired from the open bolt), the trigger, the trigger safety, the secondary safety on the pullcock and the barrel lock.

It turned out to be the next to last gun that I designed for the White Companies. It came along just as MTI folded and transformed into WhiteRifles. The powers that be at the new Co. wanted nothing to do with a new model and the design went nowhere. I only ever built one. This was basically a BG-series shotgun transformed into a rifle, but with interchangable barrels. The Doc-designed trigger safety could be switched to either the right or the left, the cocking handle also could be switched from the right to the left, the action was held down by two stock screws threaded into two fore and aft recoil lugs. The barrel fitted the action without threads but with a guide lug to center it just right and locked into the action with a quick turn thumbscrew and a barrel band. In practice, the barrel was removed by unscrewing and removing the barrel band, turning the thumbscrew a half turn, then pulling the barrel out of the action. It was replaced by slipping the new barrel into the screw-less action, replacing the barrel band and turning the thumbscrew a half turn to lock the barrel into place. It would accommodate both rifle and shotgun barrels of any length.

I have long thought that this model was the best of the slam fire in-lines rifles that I designed. The inter-changability of barrels and right to left safety and cocking should have made it a winner. Too bad it went nowhere.

[one_third] [/one_third]

[/one_third]

[one_third] [/one_third]

[/one_third]

[one_third_last] [/one_third_last]

[/one_third_last]

Proto M2004

If it had come to production, I planned on a pressure formed Zytel fiber-reinforced stock (for the stable dimensions such martial provides), with a better looking fore-end extending past the barrel band, an aircraft aluminum ramrod threaded for cleaning jag and bullet puller, double ramrod pipes, barrels in various lengths and weights by Criterion for their superb accuracy and consistent bore size, plus all the usual features of White rifles. We should still be making and selling them, but the Co. didn’t listen very well, or couldn’t.

Javelina two handed pistol and pistol sling.

I have long been fascinated with pistols, especially pistols I could hunt with. The short G -series action gave me a perfect platform for a hunting pistol. I considered the use of both hands mandatory, plus the use of a sling. I had used the 2 handed stance advocated years before with short sling around the neck attached to the pistols butt. I improved on this by designing a two handed muzzleloading pistol with an ergonomic butt plus a forward pylon for the weak hand, interconnecting the two so the pistol could be carried by the strap in one hand. I also adapted a commercial adjustable sling , attaching it to the ramrod ferrule and the other end to the butt. The sling went around the opposite shoulder and down and across the body. When adjusted correctly, I could carry it slung at my side, then use it to brace the gun at arm’s length. I called it the Javelina. White Systems made about 50 of them for a trial run in 1992 and they sold like lead balloons and went nowhere.

This was a large pistol, with ten inch barrel, weighing about 4 lbs, but shot rifle sized loads. With two hands, recoil was not a problem.

This was a large pistol, with ten inch barrel, weighing about 4 lbs, but shot rifle sized loads. With two hands, recoil was not a problem.

Razorback Pistol-Rifle–

was similar in concept to the Javelina, using the same G-series action, components and adjustable sling, but sporting a longer barrel and a folding stock. It could be used either as a two-handed pistol with stock folded or as a rifle, with stock extended. I found it to be very useful, especially for hunts requiring air travel. It’s compactness was a blessing. Despite the short barrel, it was accurate and powerful. I used it quite a lot but only ever built one. The White companies were never interested in the design.

Bobcat pistol –

was a smaller single handed pistol based on the smaller SG -series one piece barrel/action combination. It was the size of a T/C Contender single shot pistol with 8 inch barrel. I killed some big animals with this smaller pistol, but like the other pistols, it also went nowhere.

You can see how small the BobCat pistol is. Yet it was capable of killing big animals.

You can see how small the BobCat pistol is. Yet it was capable of killing big animals.

The genius of all these shorter, lightweight pistol-like guns, especially the Bobcat, was the huge loads thrown from them. A 504 bullet weighing 460 grains, with 80 grains Pyrodex-P left the Bobcat’s 8 inch barrel at 1000 FPS and was as potent a load as any modern magnum pistol.

K- series rifles –

were based on the Kalishnakov rifles of post WWll, with their gas pistons on top and barrel underneath. I designed what was basically an upside down G-series rifle, with the barreled action upside down, a new trigger and safety that worked quite well and a pistol gripped military style stock. The ramrod went atop the barrel and the red dot scope sights went on top of the stock. The combination was accurate and dependable as long as the barreled action was firmly glassed into place. I made 6 prototypes but, once again, the White companies were never interested.

This was the sporting version of the K-series. Some of the others have true vertical pistol grips. They are amazingly functional, certainly not elegant, but balance and handling are excellent, accuracy is undiminished and recoil is strikingly mild because of the under-barrel configuration.

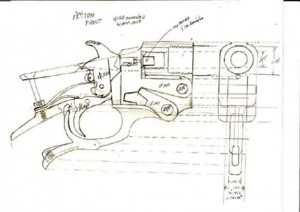

Alpha Dropping Block rifle-

was designed in response to White’s competitors bringing out falling block muzzleloading actions designed to use the newly popular 209 primer for muzzleloading. I spent about a year designing this new action, built a single one, then went to a gunshow, picked up an old German falling block rifle for a low power target cartridge and found my ‘new’ design had already been invented by someone else about a century before. I was near crushed, but the design was effective and simple, with only 3 moving parts. WhiteRifles stopped rifle production at about that time, so the design didn’t get off the ground.

[one_half] [/one_half]

[/one_half]

[one_half_last] [/one_half_last]

[/one_half_last]

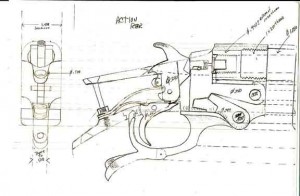

Design drawings of the falling block action I re-invented about a century late. Great minds think alike.

Varminter rifle.

White had been participating in the National Muzzleloading Manufacturer’s Match in Friendship, Indiana, put on by the National Muzzleloading Rifle Association since 2000. The original concept was to shoot commonly available muzzleloading hunting rifles in competition at paper and steel target from 25 to 150 yards. Tuning was allowed but only what an ordinary hunter might do to his hunting rifle. It soon became obvious that the various companies were doing far more than that, with special barrels, and bullets and the best of shooters. White tried competing with off the shelf rifles but their amatuer shooters usually lost badly to other more sophisticated teams. In 2007, I was approached by a group who saw the potential in the White System. As a consequence, we (the team and I) designed a .368 caliber rifle that I called the Varminter, designed for slow, meticulous shooting at small game or target. The team won that year, 2007, beating all old records for team and individual shooting by a substantial margin. Our best shooter only lost 9 points out of 300 for the match. The performance was so astounding that the match disappeared. Nobody wanted to come back to face that kind of competition. I was personally disappointed that the other companies did not rise to meet the competition.

The most accurate muzzleloading rifle in the world!!

Bore -B-Dry –

was invented in response to the need for a nipple and barrel plug to keep powder and bore dry. Back in the old days, most of us carried a roll of tape to cover the muzzle with in case of rain or wet. Tape didn’t work for the nipple, though, so often I used a broken off pencil eraser between hammer and nipple. All of them looked the same. There was a plug for the muzzle and a cover for the nipple on each one.

was invented in response to the need for a nipple and barrel plug to keep powder and bore dry. Back in the old days, most of us carried a roll of tape to cover the muzzle with in case of rain or wet. Tape didn’t work for the nipple, though, so often I used a broken off pencil eraser between hammer and nipple. All of them looked the same. There was a plug for the muzzle and a cover for the nipple on each one.

They were used in pairs, one to plug the muzzle with the other end up in front of the front sight, they were bright orange so the shooter would have a hard time missing seeing it, the muzzle plug was also used to cover the nipple, the nipple fitting into a tight recess in the cover, catching and pinching it tightly between nipple and closed hammer. The Bore-Dry was a decided improvement. They sold well, but were inexpensive so not awfully profitable. White usually used them as a loss leader, throwing in a set with any order.

336 primer

|

| Breechplug and 336 primer- a 32 S&W case with reloadable primer. |

It was obvious, to me at least, that the 209 primer was not the perfect primer for muzzleloaders, even in the special formulations that primer manufacturers came up with, of course at extra price. They were far too powerful for good accuracy and all leaked badly at the breech. In consequence, I embarked on the quest to find one that was even better. I wanted the new primer to be small enough to be unobtrusive, large enough to be handy, self-ejecting with the next load, re-loadable and self sealing at the breech. I tried designing from scratch , in fact spent several years at it, sporadically, but ended up with a common cartridge. In the end, the best one was the old 32 S&W casing. This short pistol cartridge was the first successful commercial center fire cartridge in the world. It fulfilled all the requirements that I had previously designated and in addition could be re-loaded with either regular or magnum primers and was widely available because of its popularity in the cowboy shooting game. It proved to work very well in the field. In 2004, I took it to Africa, using a moderate smokeless powder load. I killed 7 animals with 9 shots, the two extra on a Kudu, never cleaned the rifle once, had no powder residues in the breech to deal with and never extracted a primer by hand. Later, when 209 Blackhorn powder came along, with its high ignition temperature, I redesigned the breechplug internals so that a larger volume of hot gases would get to the powder. The only problem is that the 336 is only useful in a closed breech gun, like the ThunderBolt. It does not work well with a slam-fire type action like the Whitetail or Super-91. Unfortunately, all this inventiveness has come to naught. It was never commercially available except on a custom basis.

209 conversions

The 209 shotgun primer became popular with hunters because it worked better in our competitor’s rifles with their overlong breechplugs. They did not become popular with target shooters because the blast was too strong and resulted in deteriorating accuracy. The job turned out to be more complicated than it looked. Turning a Nipple breechplug into a 209 holding breech-plug was not hard but researching the exact size of the pocket was more difficult. It had to be tight enough so back-blast was not an excessive problem and loose enough so the 209 would come out of the pocket after the shot in spite of fired powder residues. Discovering the compromise took a while. So did discovering a way to keep the unfired 209 in the pocket, a small wire with sharp end the final answer. I also had to get rid of the counterbore in the #11 plug and make it solid so the flame would be a little cooler when it hit the powder. The hammer was changed from a nipple striker to a firing pin. It was used with the old cocking handle and hammer spring. They are currently available from Whiterifles.com on the net.

DOC’s Water Displacing Oil –

was developed in response to a request for an effective, high grade, combination lubricant and rust inhibiting oil. Usually, oils do one or the other best, not both. It took a while to find the almost perfect oil that satisified that requirement and was also available in industrial quantities so White could repackage it. The oil really shines because in it’s fresh state it is a great lubricant, once applied and as time passes it dries and plates out on metal surfaces, providing long time protection from water, vapor and corrosives. It will also not harm gun stock finishes, but actually enhances the glow. It’s great stuff.

was developed in response to a request for an effective, high grade, combination lubricant and rust inhibiting oil. Usually, oils do one or the other best, not both. It took a while to find the almost perfect oil that satisified that requirement and was also available in industrial quantities so White could repackage it. The oil really shines because in it’s fresh state it is a great lubricant, once applied and as time passes it dries and plates out on metal surfaces, providing long time protection from water, vapor and corrosives. It will also not harm gun stock finishes, but actually enhances the glow. It’s great stuff.

Superchargers

The White Muzzleloading System’s emphasis on fast second shots required the development of a way to facilitate rapid reloading. Cartridges of various kinds had long been the answer to the problem. The Revolutionary soldier’s ability to get off 4 shots minute depended on the availability of paper cartridges to speed handling powder and ball. This was also true during our own Civil War when the Minie Ball, really a short bullet, was the projectile of choice. Paper is much more fragile than plastic and plastic is reloadable. Obviously, plastic would be the better choice. The only real question was the form that it finally took. The problem basically was that the System promoted a long projectile and storing it a cartridge then getting that long bullet into the muzzle was the problem. The solution was a plastic charger that held powder in one end and bullet in the other, with a bullet nose fitting partition between the two but open enough to admit the ramrod, the bullet cavity sized to fit the caliber. In use, the charger was best carried on the buttstock or belt in an elastisized carrier from which it could be quickly snatched and flicked open, dumping the powder charge into the barrel. The charger was then reversed and the small end of the ramrod used to push the bullet out of the opposite end directly into the barrel. The charger was then dropped or better stored, then the ramrod used to finish pushing the bullet down the barrel. White ramrods were designed to be used without the need to turn them around, which also speeded the process.

Thumbhole stocks

The only inventiveness exhibited here was the ergonomic, functionally elegant design, usable by right or left-hander without modification.. But then, that’s how all my stocks were designed: with functional elegance in mind. Just seeing the stock, let alone handling it, should immediately teach the docrtine of its use and function, without any formal instruction.

One of my thumbhole stocks on a White Super 91-II

PowerLube-

was developed only because the commercial

was developed only because the commercial

bullet lubes than available did not work awfully well, the problem being their hardness when cold and gooyness when warm. The temperature variation that they would tolerate was not great, which meant that shipping a pack of bullets to Texas in a hot UPS van was a guaranteed way to melt the lube into a mucky mess in the package. We finally found a solution in a lubricant available from a smalltime manufacturer, an inventive genius in his own right. All I did was order it in White’s identifying blue color. We used it to lubrisize White bullets and sold it in small flat cans and sticks for shooter use.

Super Blue Moly grease-

When I first designed the nipple-breechplug for White System rifles, it quickly became apparent that they needed to be greased when installed. If fired dry, they were very difficult to remove, as all breechplugs are when used with black powder or substitutes. The best grease for breechplugs that we found early on was bicycle chain grease. Later on, the US military solved the problem for us by coming up with molybdenum containing anti-seize, which as a great improvement. One of the nice things was that moly containing anti-seize is naturally a dull blue, White’s selected identifing color. It is a terrific product for high temperature uses.

Wipe-Away cleaner

White wanted a cleaner that was proprietary to the White System, which essentially matched black powder or substitute residues against stainless steel. I found the match in the stainless steel cleaners used in most hospitals for cleaning stainless surgical tools and hardware. It proved to be a combination of water, several alcohols, spreading factor and a non-sudsing detergent. The combination proved to be terrifically effective for cleaning black powder rifles. We added a blue color to make it identifiable as a White product.

White wanted a cleaner that was proprietary to the White System, which essentially matched black powder or substitute residues against stainless steel. I found the match in the stainless steel cleaners used in most hospitals for cleaning stainless surgical tools and hardware. It proved to be a combination of water, several alcohols, spreading factor and a non-sudsing detergent. The combination proved to be terrifically effective for cleaning black powder rifles. We added a blue color to make it identifiable as a White product.

BULLETS

Comments

Add comment

No comments yet.